Source = Samsung Elec.

Samsung Elec. today announced financial results for the first quarter ended March 31, 2016. Samsung’s revenue for the quarter was KRW 49.78 trillion, an increase of 5.7 percent YoY, while operating profit for the quarter was KRW 6.68 trillion, an increase of 12 percent YoY. In the company’s earnings guidance disclosed on April 7, 2016, Samsung estimated first quarter consolidated revenues would reach approximately KRW 49.0 trillion with consolidated operating profit of approximately KRW 6.6 trillion.

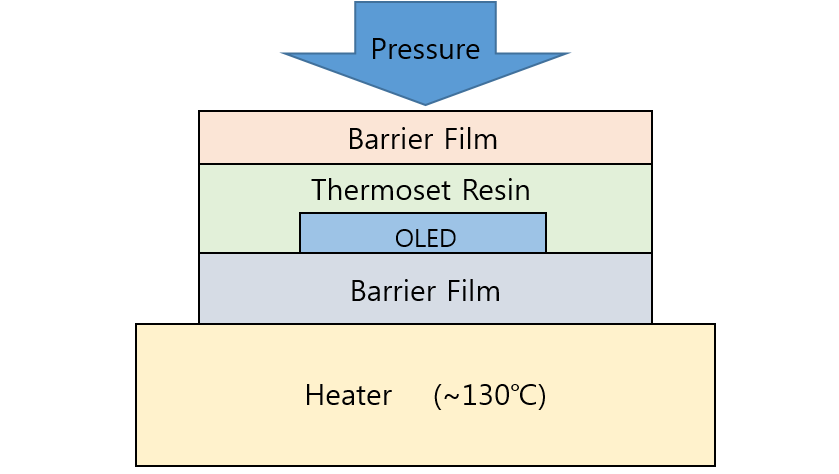

The first quarter saw overall earnings growth led by the early launch and successful sales of the flagship Galaxy S7 and S7 edge, improved memory product mix, expanded 14nm supply of System LSI products and increased sales of OLED panels.

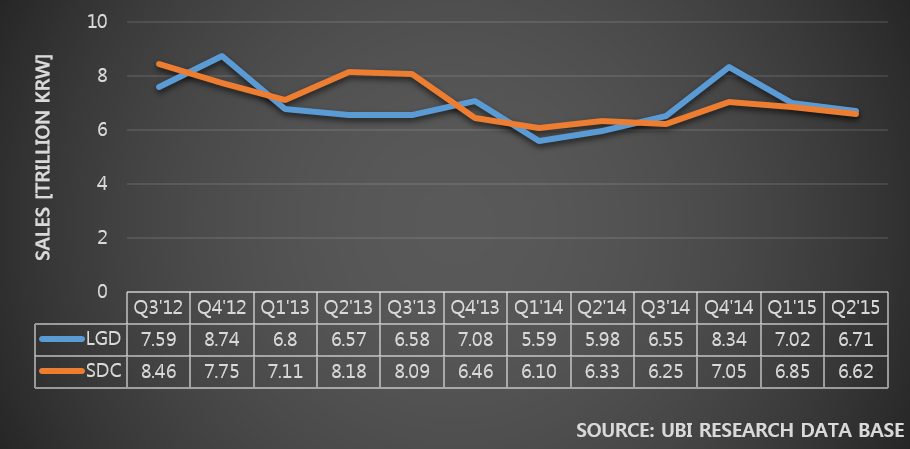

Overall earnings of the Display Panel business decreased due to a sharp decline in LCD panel earnings although earnings of OLED panels improved mainly driven by the Galaxy S7. The LCD business experienced temporary yield issues while adopting new process technology as well as TV panel price decline.

The IT & Mobile Communications (IM) Division saw a substantial earnings improvement both YoY and QoQ mainly driven by the early launch of Galaxy S7 and its strong sales and improved cost efficiency through the streamlining of mid-to-low-end smartphone lineups. Although the company had a one-time royalty settlement expense in the quarter, the impact on operating profit was equivalent to less than 1 percent of IM revenue.

The Consumer Electronics (CE) Division achieved significant earnings growth YoY led by expanded sales of premium TV models such as SUHD TV and Curved TV in developed markets, and also a notable sales increase of premium home appliance products in North America.

In the second quarter, the company expects its solid performance to continue led by steady earnings in the Mobile and Semiconductor businesses plus improvement of the CE and Display Panel businesses.

The IM Division is expected to secure solid earnings by expanding sales of the Galaxy S7 along with strong profitability of mid-to-low-end products. The CE Division expects to see improvements as seasonality should improve air conditioner sales, while flagship SUHD TV sales are expected to increase.

The Display Panel segment is expected to see earnings improvement compared to the previous quarter as LCD profitability is forecast to rise on stabilized TV panel yields and improved demand and supply conditions.

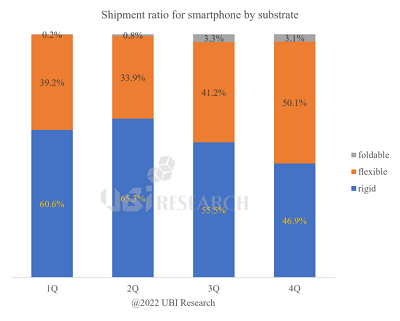

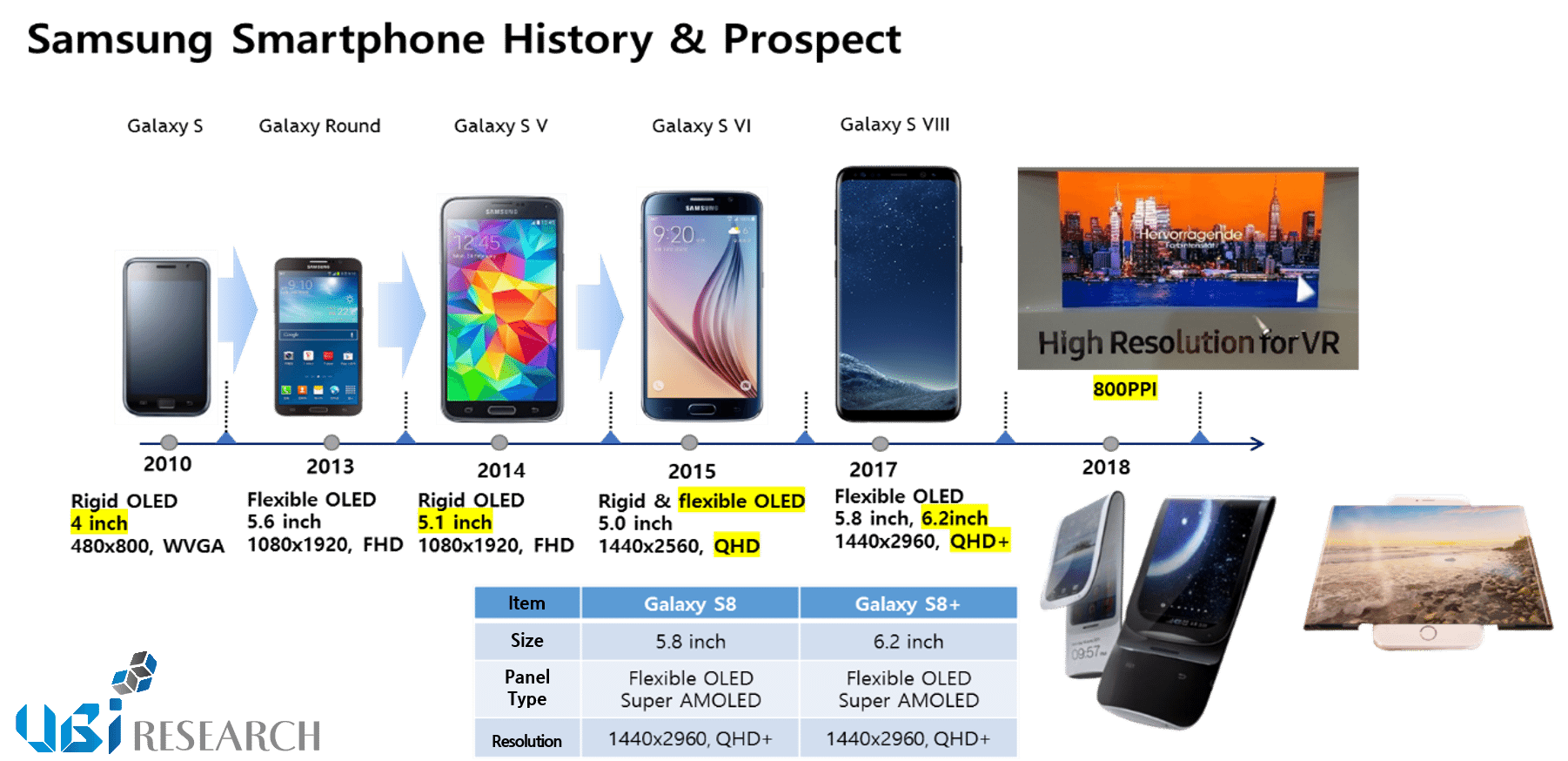

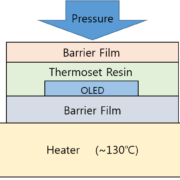

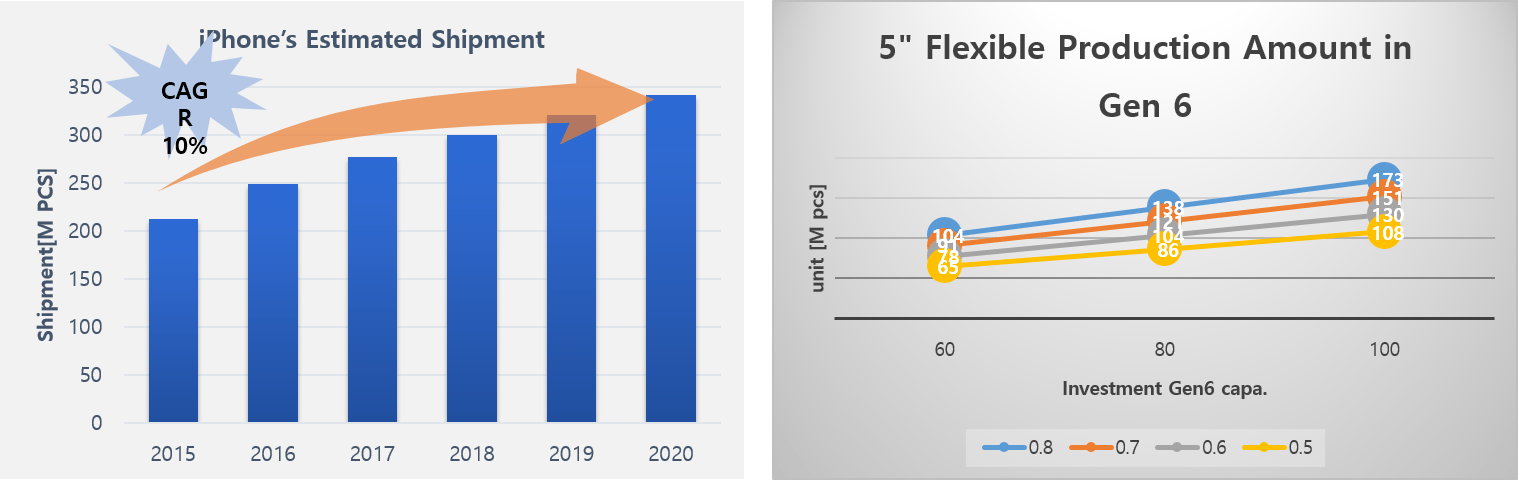

For the Display Panel business, OLED earnings are expected to improve due to growth driven by an increase in flexible and high-resolution panels. LCD panel profitability is expected to improve in the second half driven by high valued-added products amid better supply and demand conditions.

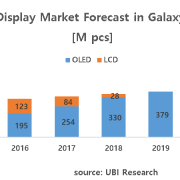

For the IM Division, the company expects the sales of flagship products to increase YoY, especially with strong demand for flagship products such as the Galaxy S7 and new model launches in the second half. In addition, the company will continue to manage cost efficiencies by streamlining its smartphone lineups.

For the CE Division, the company will focus on profitability by increasing premium products such as SUHD and Curved TVs. With the Olympics and other global sporting events forecast to drive global demand for large-size TVs, the company expects strong improvements in operating results YoY.

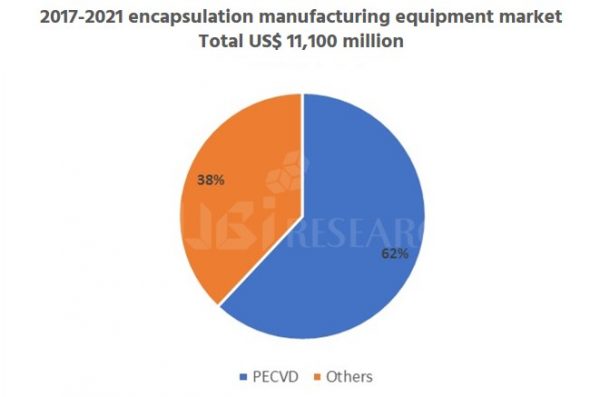

Meanwhile, capital expenditure (CAPEX) for the first quarter was KRW 4.6 trillion, which includes KRW 2.1 trillion for the Semiconductor business and KRW 1.8 trillion for the Display Panel business. The annual plan for CAPEX has not yet been confirmed but is projected to increase slightly compared to last year’s CAPEX based on various business opportunities. CAPEX for the Display Panel segment may increase as the company sees strong market demand for OLED panels. DRAM CAPEX will remain flexible based on supply and demand conditions but is expected to be lower than 2015.

The Display Panel segment posted KRW 6.04 trillion in consolidated revenue and KRW 0.27 trillion in operating loss for the quarter.

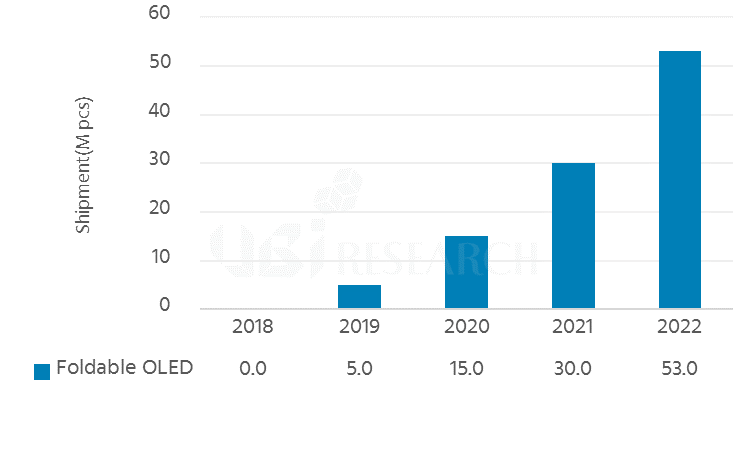

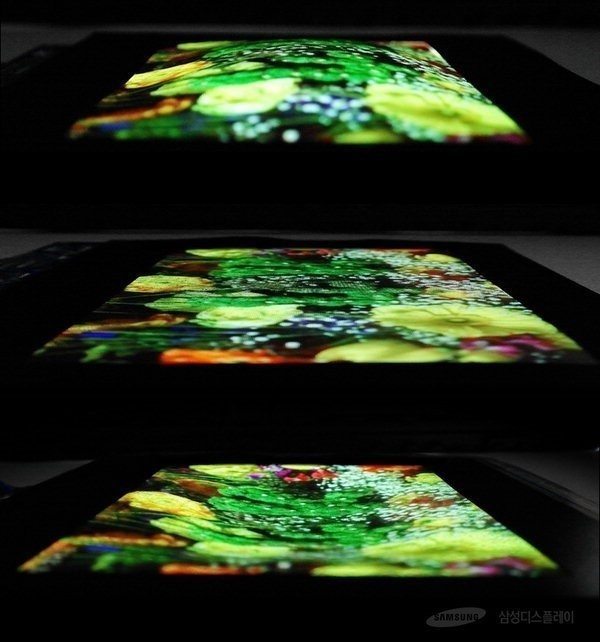

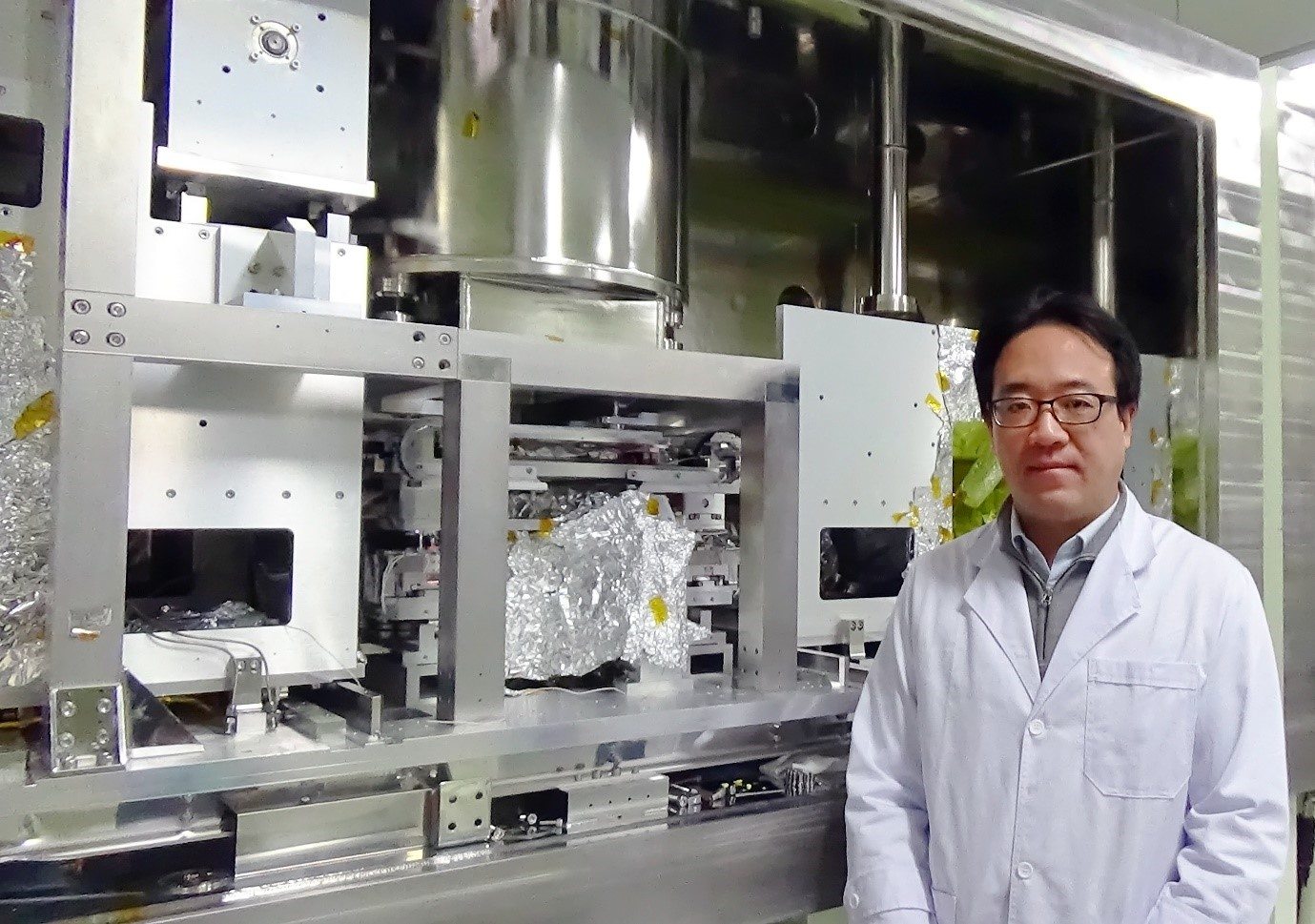

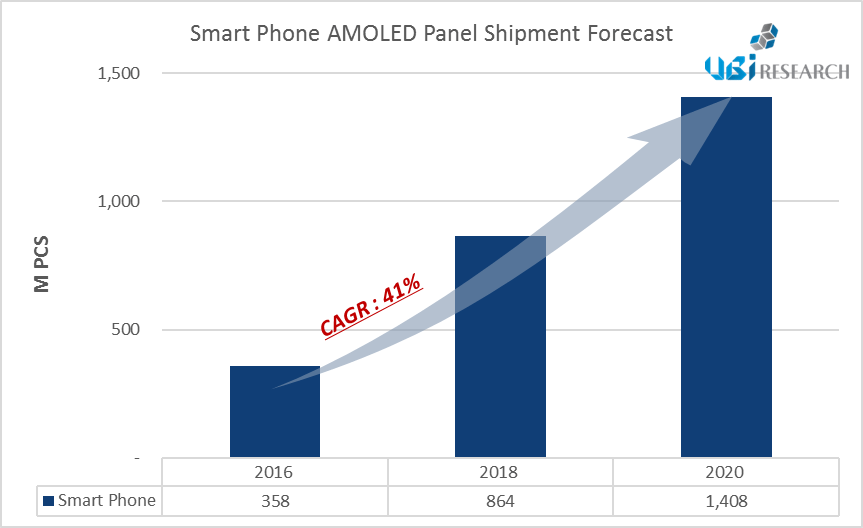

In the first quarter, shipments of OLED panels improved from the previous quarter, driven by launches of new high-end smartphone panels and strong demand for smartphones in the mid-to-low-end space. Conversely, the company’s LCD panel shipments decreased, affected by weaker demand during low seasonality.

Looking ahead to the second quarter, for OLED panels, Samsung hopes to actively address demand for new products and expand its customer base, while focusing on improving profitability of LCD panels by increasing shipments of strategic premium products such as UHD and large-size panels.

In 2016, the company expects OLED demand will continue to rise helped largely by growth in the mid-to-low-end smartphone segment while the LCD market will continue to be over supplied. In this market, Samsung hopes to actively address demand for new products, increase sales of value-added products and reinforce its leadership by developing new panel applications.

The IM Division – comprising the Mobile Communications and Networks Businesses – posted KRW 27.60 trillion in consolidated revenue, a 6.6-percent YoY increase, and KRW 3.89 trillion in operating profit for the quarter, a 42-percent YoY increase.

While smartphone and tablet demand saw a slight QoQ decrease due to seasonal effects, overall operating profit for the Division increased. This increase was largely due to the early launch and strong global performance of the flagship Galaxy S7 and S7 edge, as evidenced by robust sell-out figures and low inventory levels compared to their predecessors. A streamlined mid-to-low-end smartphone lineup also contributed to improved profitability.

Looking ahead to the second quarter, while demand for smartphones and tablets is forecast to remain flat due to continued weak seasonality, the worldwide rollout of the latest flagship models as well as an increase in shipments of the mid-to-low-end Galaxy A and J series are expected to help the company maintain robust sales momentum and profit.

As for the year ahead, Samsung anticipates softening demand in the smartphone market and negative growth in the tablet market. The company will reinforce its leadership in the premium smartphone segment on the back of the Galaxy S7 and S7 edge, while continuing to increase volume and improve profitability in the mid-to-low-end segment. In addition, the company will continue to expand the Samsung Pay service to global markets and look into new business opportunities.

For the Networks Business, the company will seek growth through the continued rollout of 4G LTE services in new markets around the world, including Southeast Asia.

The Consumer Electronics Division – encompassing the Visual Display (VD), Digital Appliances (DA), Printing Solutions and Health & Medical Equipment (HME) businesses – posted KRW 10.62 trillion in consolidated revenue and KRW 0.51 trillion in operating profit for the quarter.

In the first quarter, TV market demand decreased YoY due to weak seasonality and economic downturn in emerging markets. Earnings for the VD Business showed significant growth YoY, led by increased sales of premium products such as SUHD and Curved TVs.

For the appliances business, earnings improved compared to the corresponding quarter last year, led by continued growth in the North American market and increased sales of innovative premium products such as Chef Collection refrigerators and the Activewash™ washing machine.

In the second quarter, TV demand is expected to slightly increase riding on sports events such as the Olympics. The company plans to further improve profitability by continuing to focus on the new and improved SUHD TVs with the world’s only cadmium-free Quantum dot display, while also increasing sales of premium products such as UHD TVs and Curved TVs.

Digital appliance demand is expected to rise due to seasonal growth for air conditioners, despite global market uncertainties. Against this backdrop, Samsung aims to increase profitability by expanding sales of innovative premium products such as a newly launched air conditioner and Family Hub Refrigerator. Additionally, the company expects to improve performance by expanding its enterprise business including built-in kitchens and system air conditioners.

China Trend Report Inquiry

China Trend Report Inquiry