[China Trend Report] Visionox Orders 6th Generation Vertical Vapor Deposition for IT

According to a Chinese trend report published twice a month by UBI Research, Visionox ordered sixth-generation vertical vapor deposition machines for R&D on the V3 line.

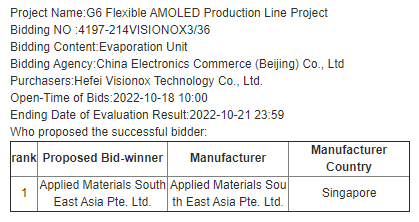

Visionox Ordered Vertical Vapor Deposition, Source: Chinabidding.com

Visionox’s V3 line is operated on with 30K/Month to mass-produce flexible OLEDs and this investment was done mainly on deposition process equipment in the spare space of the V3 site without investing in cells or module process equipment for IT.

The 6th generation vertical vapor deposition machine invested by Visionox this time is considered to be a prior investment to secure the technology of vertical vapor deposition and to determine the possibility of mass production in the 8th generation or higher in the future. The deposition process in the existing OLED line is being carried out as a horizontal deposition process and due to the issue of ledger glass and FMM control, FMM technology is applied to half-cut in the 6th generation line for mobile devices and open-mask technology in the 8th generation line for TV.

Since glass and masks are less affected by gravity than horizontal deposition, vertical deposition has the advantage of securing greater productivity by allowing deposition without cutting the ledger glass. However, mass production is still unclear.

If Visionox secures technology for vertical deposition through this investment, it is expected to invest in new lines for 8.5th generation IT without half-cut in the future.

China Trend Report Inquiry

China Trend Report Inquiry