OLED Daily Issue, April 23, 2019

(Full text of articles: http://news.donga.com/3/all/20190421/95157197/1)

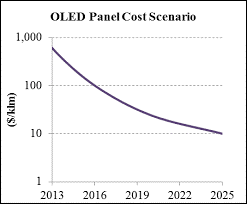

The Chinese companies’ volume offensive raised concerns that the OLED industry, following liquid crystal displays, could face oversupply problems. Analysts say that while South Korean display manufacturers’ performance in the first quarter has deteriorated due to a sharp drop in prices of LCD panels, even OLEDs, which are seen as new growth engines, could be on the verge of oversupply in the near future.

According to a recent report released by Hana Financial Management Research Institute on Monday, the production capacity of OLED plants currently being built by Chinese companies such as BOE, CSOT and TCL is twice that of South Korea.

(Full text of articles: https://www.hankyung.com/economy/article/2019042211521)

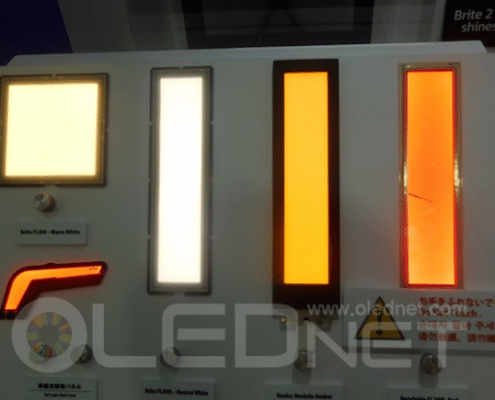

LG Group is speeding up efforts to reorganize its business portfolio for future growth. LG Display’s decision to withdraw from its organic light-emitting diode (OLED) business for general lighting is part of its objection. The “choice and focus” strategy has become a keyword that penetrates LG Group Chairman Kwang-mo Koo “New LG,” who headed the group last year.

According to LG Group and others on the 22nd, LG Display has given up its OLED business for lighting that it has been pushing as a new growth engine. It has been about a year and six months since it started mass-producing products from new OLED production lines.

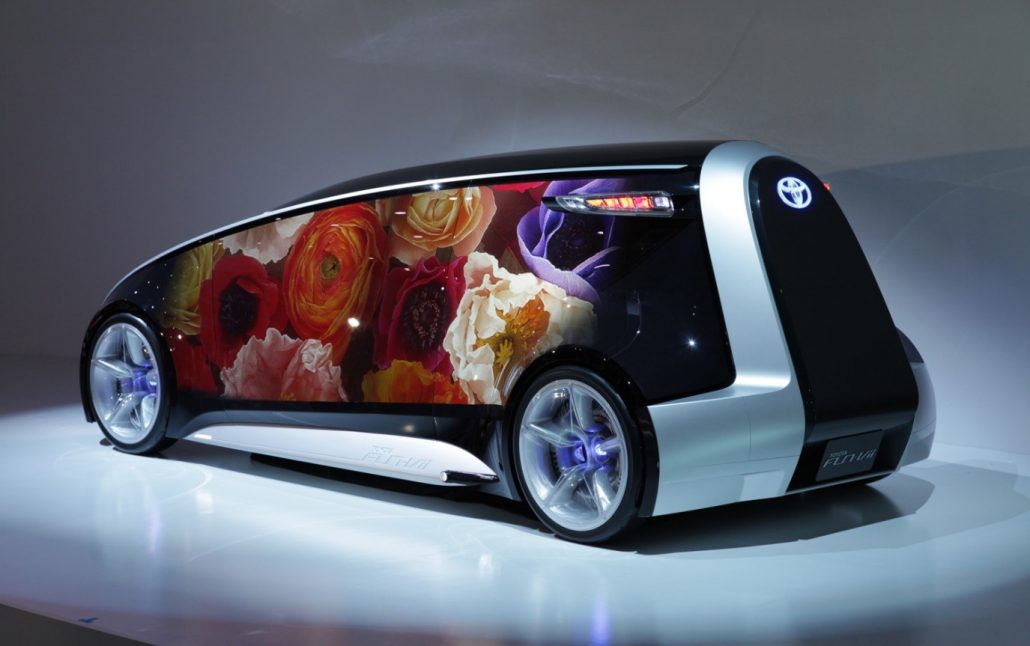

It is heard that LG Display has decided to withdraw from markets by gradually reducing mass production of OLEDs for lighting that are produced at 5th generation OLED lines (P5) in Gumi, North Gyeongsang Province. Instead, it has decided to focus on OLED markets for vehicles that have huge growth potential and can produce synergy with the group’s automotive electric field (electric and electronic devices) business. LG’s acquisition of ZKW, which is a global automotive headlamp manufacturer, also affected LG’s ability to provide lighting for vehicles.

LG Display entered the general lighting market by introducing a new brand called ‘Luplex’ at the end of 2017. However, it is rumored that it has decided to give up its business after losing out on price competition from current LED (light emitting diode) lighting companies.