[GLOBAL TECH KOREA 2021] Solus Advanced Materials ‘Expansion of new businesses other than light emitting materials such as high refractive filler and TFE’

At ‘GLOBAL TECH KOREA 2021’ held in September 2021, Taehyung Kim, Head of Electronic Materials Business Division, Solus Advanced Materials made a presentation under the theme of ‘Solus’ Giant Step To Lead OLED Materials Technology’.

Solus Advanced Materials has monopolized the HBL market for over 8 years as a domestic display material specialist. Director Kim of Solus Advanced Materials said, “During the development of HBL, we also developed ETL with similar chemical structure and important compatibility with HBL. The performance is evaluated as equal to or higher than that of other companies’ top performance, and it will be able to enter the market soon.”

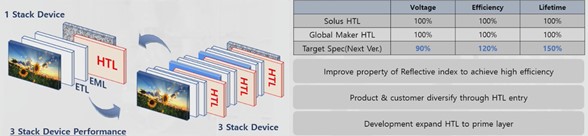

Director Kim said, “Originally, we mainly developed ETL or HBL related to electronics, but it was difficult to develop from the perspective of the overall device, so we developed HTL related to hall.” In addition “The development of HTL was completed about two years ago through joint development with LG Display, and it was approved for large panel use in May” he said. He also said, “The panel supply is gradually increasing and will be expanded to the Guangzhou line by next year.”, “HTL is structurally related to g-prime for mobile, so it is expected that it can be expanded to g-prime on the mobile side,” he said.

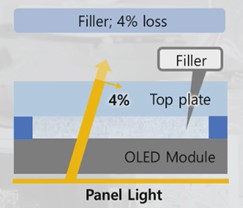

Solus Advanced Materials is developing not only light-emitting materials, but also high-refractive fillers and TFEs. Director Kim said, “The mass production of fillers will be visible from this year. There are various materials such as epoxy, urethane, and acrylic type, and we plan to mass-produce the refractive index and viscosity control according to customer specifications.”

In the TFE sector, General Manager Kim said, “The permittivity of TFE currently used in the market is 3.0 or higher, and we received a request to lower the permittivity of the monomer by 30% or more to increase touch sensitivity two years ago and have been developing it. “The permittivity of the TFE monomer being developed by Solus is down to 20%, and the UV CUT function has achieved a specification of less than 5% at around 400 nanometers, and it is being promoted and tested by customers.”

Solus Advanced Materials is currently expanding its OLED-related businesses to various OLED-related luminescent materials such as HBL, ETL, and HTL, as well as high-refractive materials and TFE monomers. It is noteworthy in which areas these various business groups can shine in the future.