OLEDON unveils plane source deposition technology for ‘super-gap’ OLED manufacturing.

Attention is growing since OLEDON, a venture company developing OLED deposition equipment, unveiled plane source deposition technology for OLED manufacturing to maintain ‘a superb gap with the competing countries’, at IMID2018, held in COEX, Seoul, Oct. 24, 2018.

Hwang Chang-Hoon, CEO of OLEDON, said, “Korea should actively invest in the development of creative deposition technology to maintain the first place in the current OLED producing countries.” He expects that plane source deposition technology is to be used both for small and medium size OLED and large area OLED manufacturing in future.

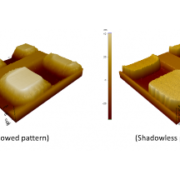

OLEDON is developing the world’s first curved plane source FMM deposition technology, which is an ultra-high-resolution OLED deposition technology capable of manufacturing 2250ppi AMOLED. The shadow distance of fine pattern can be up to 0.18um, enabling 11K high-resolution AMOLED pattern process.

<Existing FMM deposition pattern (left) and plane source FMM deposition pattern (right), Source: OLEDON>

According to Hwang, this process was confirmed with 800 ppi shadow mask, and the emission area of the pattern deposited with plane source was 1.7 times higher than the conventional deposition method.

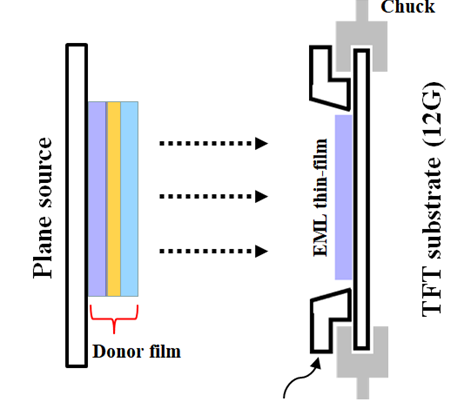

On the other hand, OLEDON holds the original patent for the FMM deposition technology of plane source, and has recently applied for a patent for vertical plane source deposition for large area OLED TV manufacturing.

<Vertical plane source deposition for OLED TV manufacturing, Source: OLEDON>