[IMID 2018] Can Blue TADF and Hyperfluorescence meet both efficiency and lifetime?

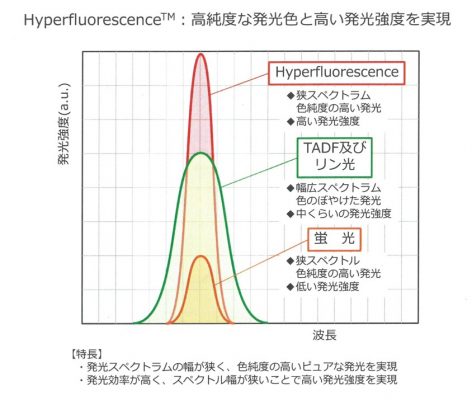

At IMID 2018 in Busan, BEXCO on August 31, Junji Adachi, CEO of Kyulux disclosed the performance of hyperfluorescence, which adds TADF dopant to the existing fluorescent host and dopant.

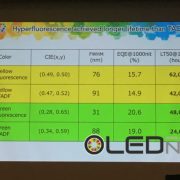

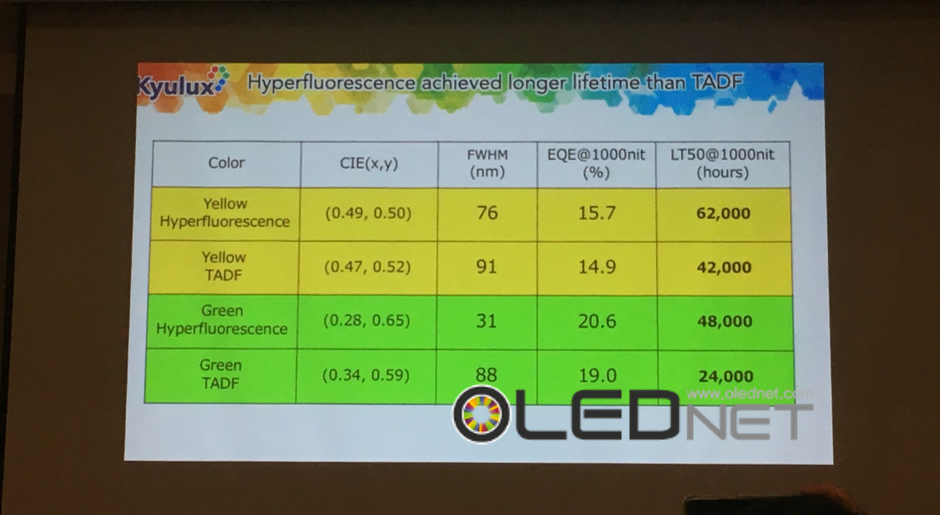

The color coordinates of the yellow hyperfluorescence revealed by Junji Adachi are (0.49, 0.50), the FWHM (Full Width at Half Maximum) is 76 nm, the EQE is 15.7% on 1000 nit basis, and the LT50 is 62,000 hours by 1000 nit. And the color coordinates of the green hyperfluorescence are (0.28, 0.65), the FWHM (Full Width at Half Maximum) is 31 nm, the EQE is 20.6% on 1000 nit basis, and the LT50 of 1,000 nit is 48,000 hours.

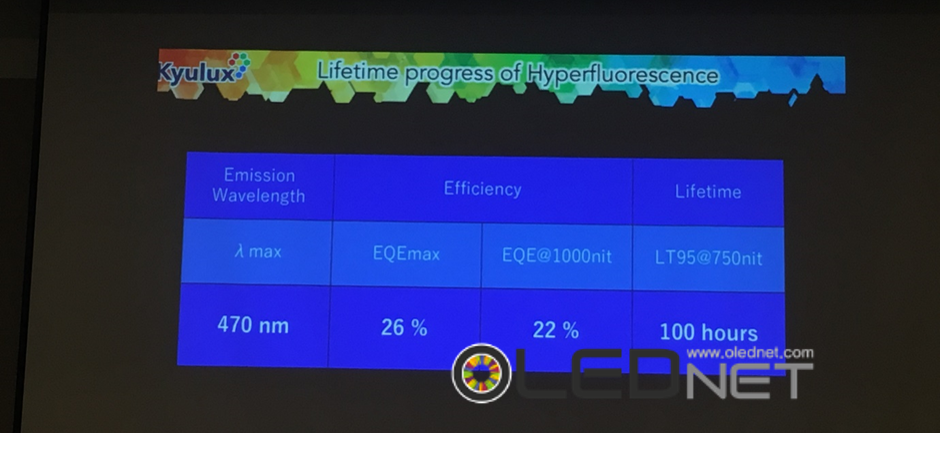

Junji Adachi also revealed the performance of Blue hyperfluorescence, which is currently under development. The maximum emission wavelength of the blue hyperfluorescence is 470 nm, the EQE at 1000 nit is 22%, and the LT50 at 750 nit is 100 hours. In particular, he predicted that the performance of Blue hyperfluorescence would be further improved in the future, saying that it began to improve rapidly in the first half of 2018.

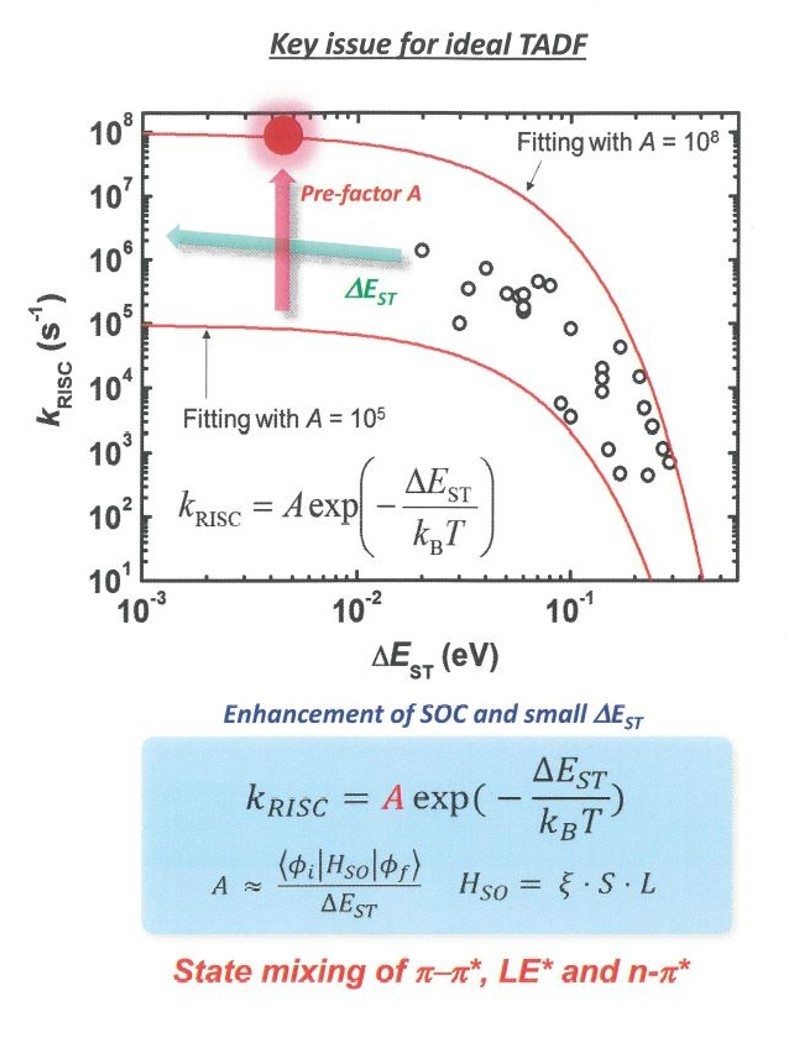

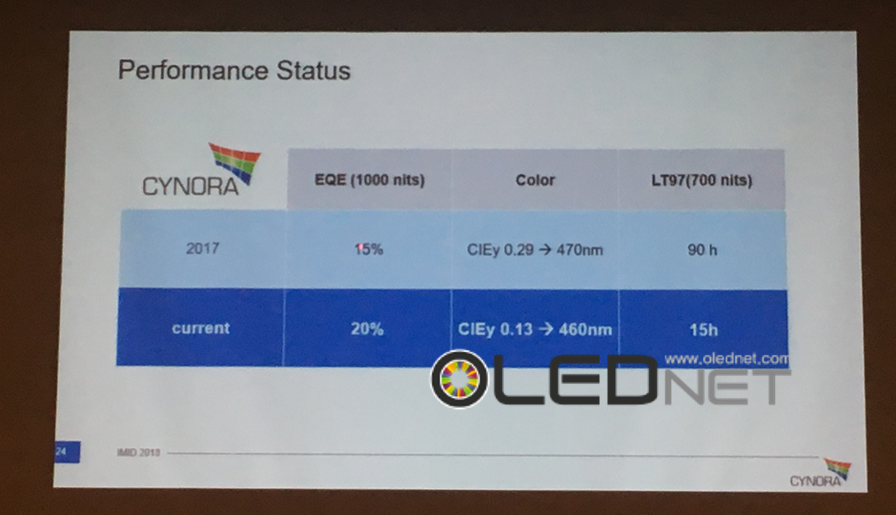

In the following announcement, Dr. Georgios Liaptsis of CYNORA explained about the deep Blue under development, emphasizing that the wavelength should be 460 nm and the CIEy should be within 0.15. He revealed its performance, adding that CYNORA has been carrying out the necessary research to make the lifetime of deep Blue as long as that of sky Blue even with phenomenon that the life span is getting longer as the Blue goes closer to the sky Blue

Fluorescent blue is currently used for the Blue of all OLED applications. Attention is growing whether Blue TADF or Blue Fluorescence can be commercialized to realize better efficiency and lifetime than existing fluorescent blue.