Reduce OLED manufacturing time to 1/10

Manufacturing technology has been developed to quickly fabricate OLED.

The Korea Research Foundation (KFRI) announced the Yun, Hongseok research team at Hanbat National University has developed a high-speed transfer technology that can effectively transfer multiple thin OLED layers to desired locations through high-pressure air jet injection.

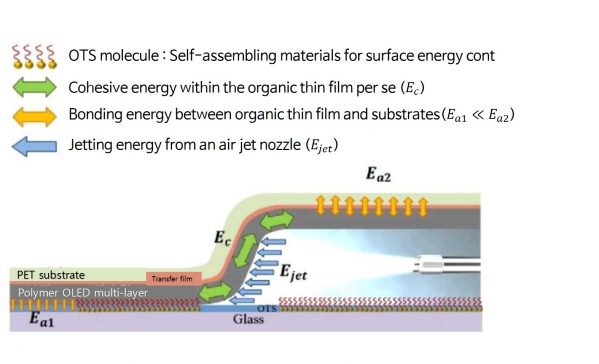

The OLED transfer separates multiple layers of thin film from the substrate all at once and combines them with other thin films to produce a device. At this time, the thin film is ripped apart or wrinkled, and the corner is torn off, which make it difficult to mass-produce.

<A conceptual diagram of energy transfer process of polymer OLED multilayer thin film using air jet, Source: Korea Research Foundation>

The team used the principle of effectively controlling the bonding energy between the thin film and substrate by a high-speed peeling technique using the air jet technology,. An air jet close to the sonic speed is injected between the substrate and OLED thin film to effectively reduce the bonding force with the substrate, thereby enabling the transfer without damaging the thin film. The high-speed transfer method through the air jet requires only short time to transfer the OLED; the processing time takes about 1/10 of production time. OLED thin films can be manufactured at low cost by coating them with a solution.

Professor Yoon, Hongseok explained, “This research has developed a technology that can rapidly manufacture OLED device because they can be effectively transferred all at once by using an air jet without damaging the OLED thin film. The unit production cost of OLED can be significantly reduced, which has been used in a wide range of applications such as OLED lighting, advertising and display. It is expected to be applied to basic electronic devices in the future such as solar cells and semiconductor devices. ”

The research was carried out with the support of the Researcher Support Project for the Basic Research Support Program of the Korea Research Foundation and was published in the international journal on nanomaterials applications, Nanoscale.