Visualization of display for mirror-less automobiles, Green light to OLED display

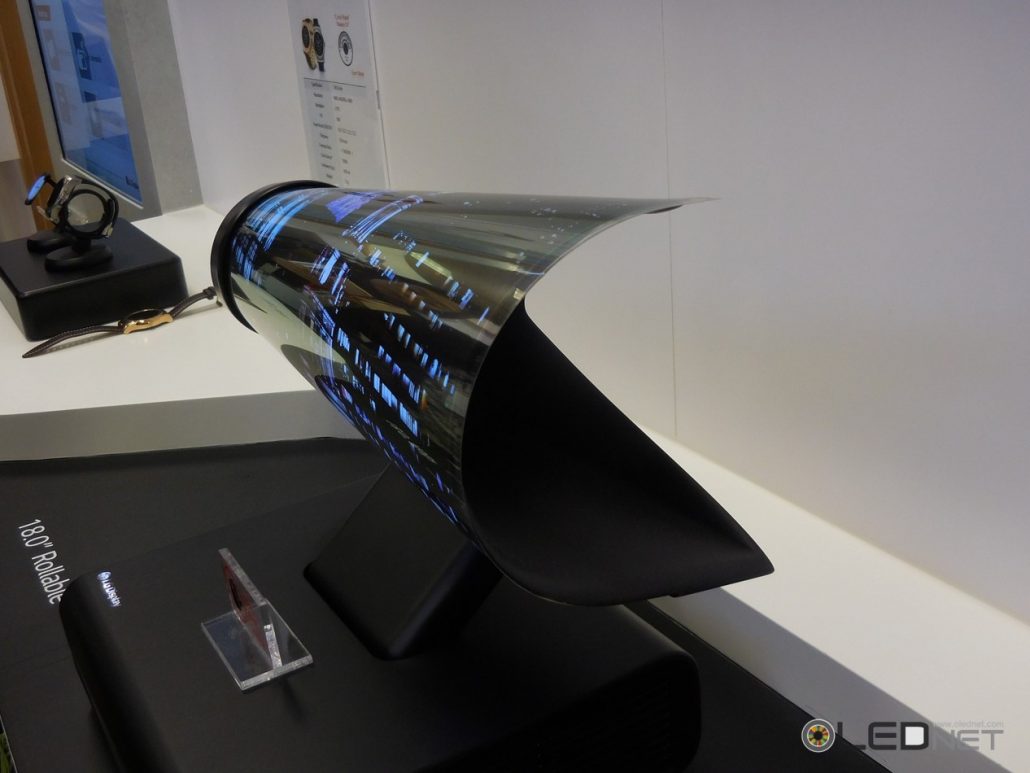

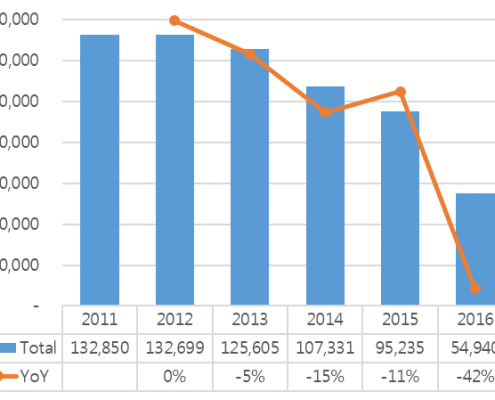

After Ministry of Land, Infrastructure and Transport did pre-announcement of legislation about partial revised plan of ‘Regulations on the performance and standards of automobiles and auto parts’ on the 7th, interests in ‘mirror-less automobiles’ having not side mirror (rearview mirror) are getting hot. This is a method of securing eyesight through display screen in the car after installing subminiature camera to car front and rear and also front doors of both sides, and solving blind zone problem which was the defect of existing side mirror and improving fuel efficiency and designs are expected, even though there are problems on functional errors and design development.

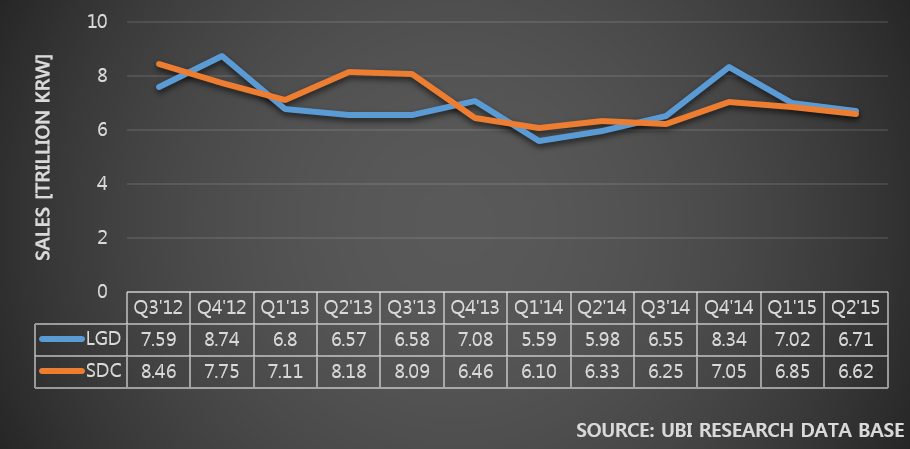

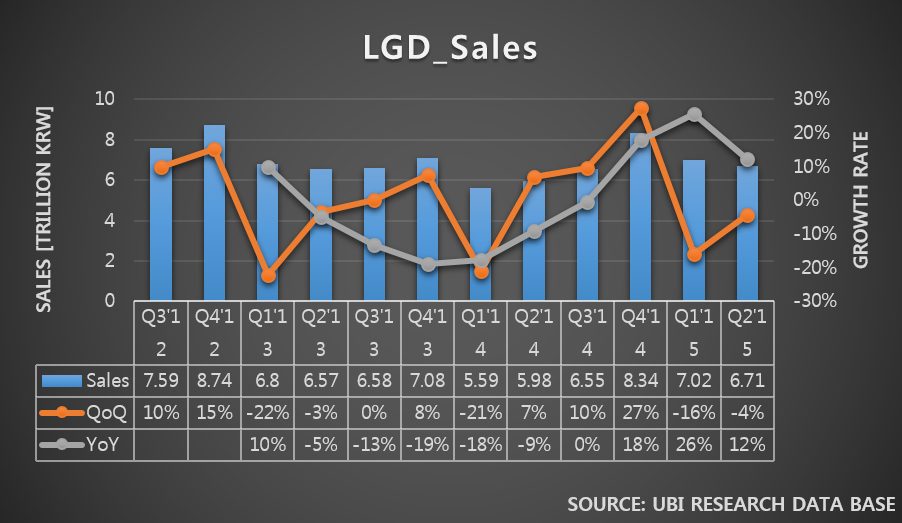

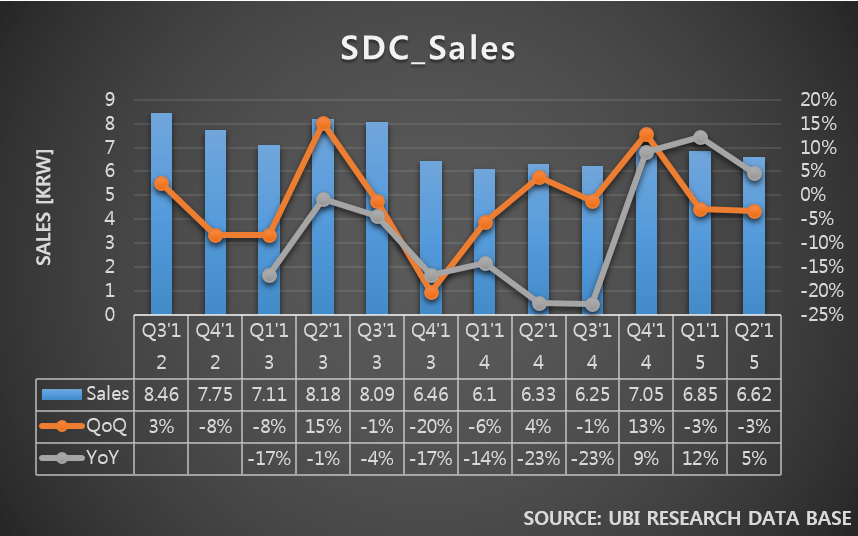

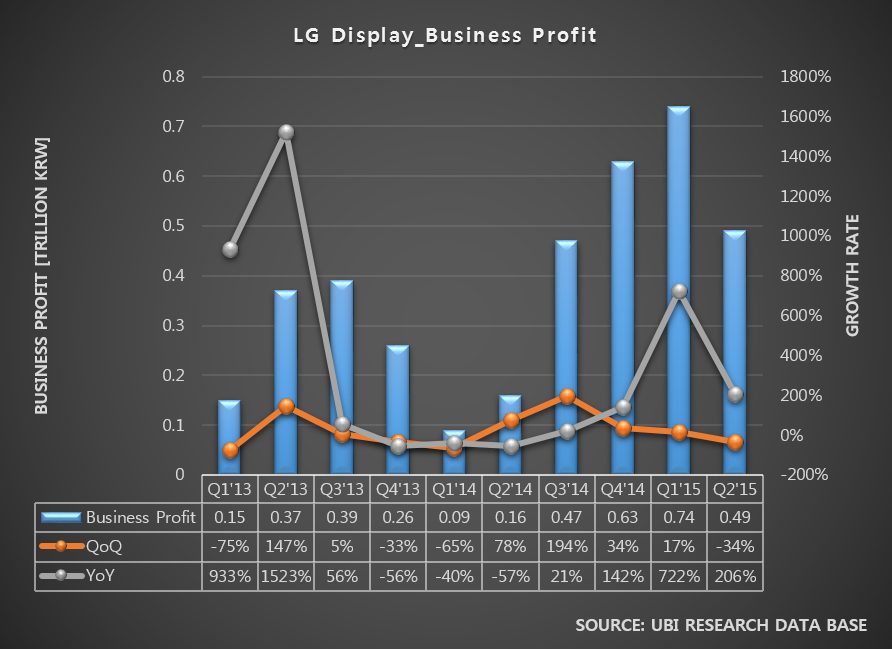

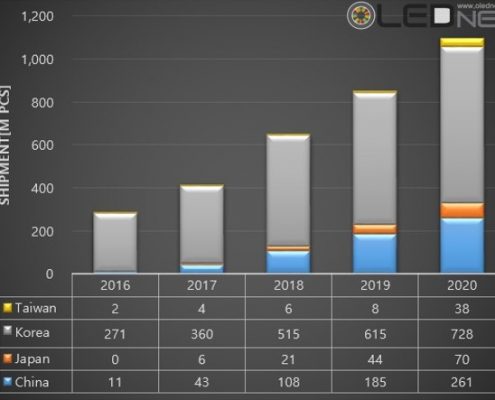

Thus, display for mirror-less automobiles is getting attentions as a drive of new market in display market for automobiles. Display fields for automobiles belongs to the industry to which creating high added value is expected because further customization is required compared to mobile and TV. So LGD or SDC panel enterprises are developing products for market penetration, and two companies are known as setting up policy of progressing differentiating strategies differently from Taiwan, Japanese companies by focusing on Flexible OLED especially.

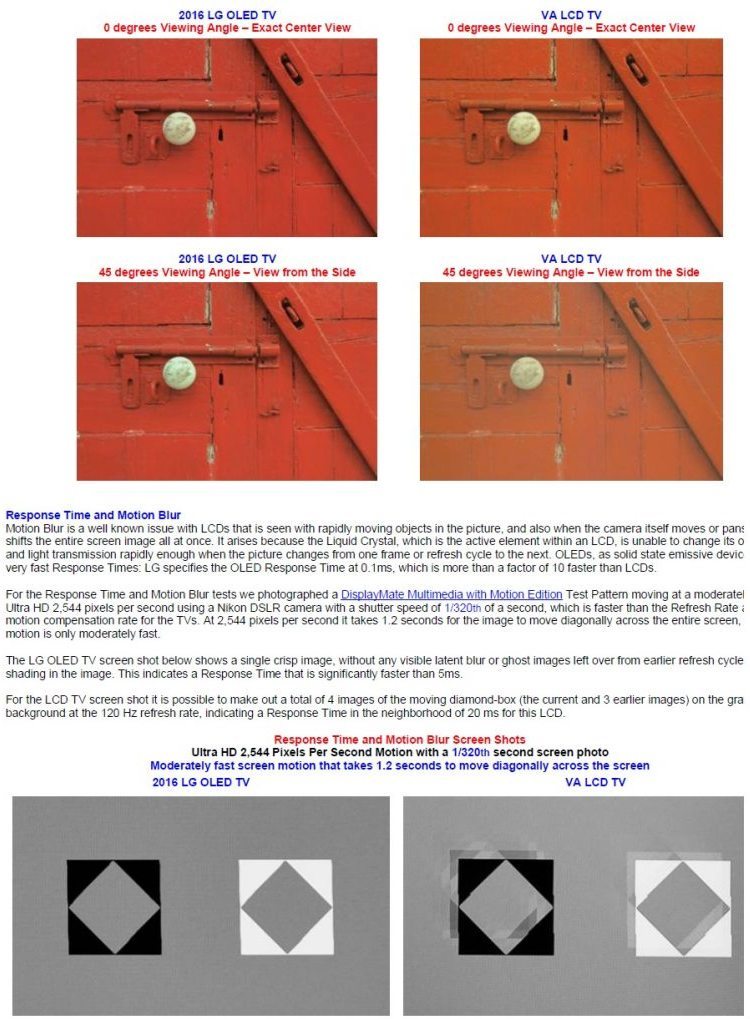

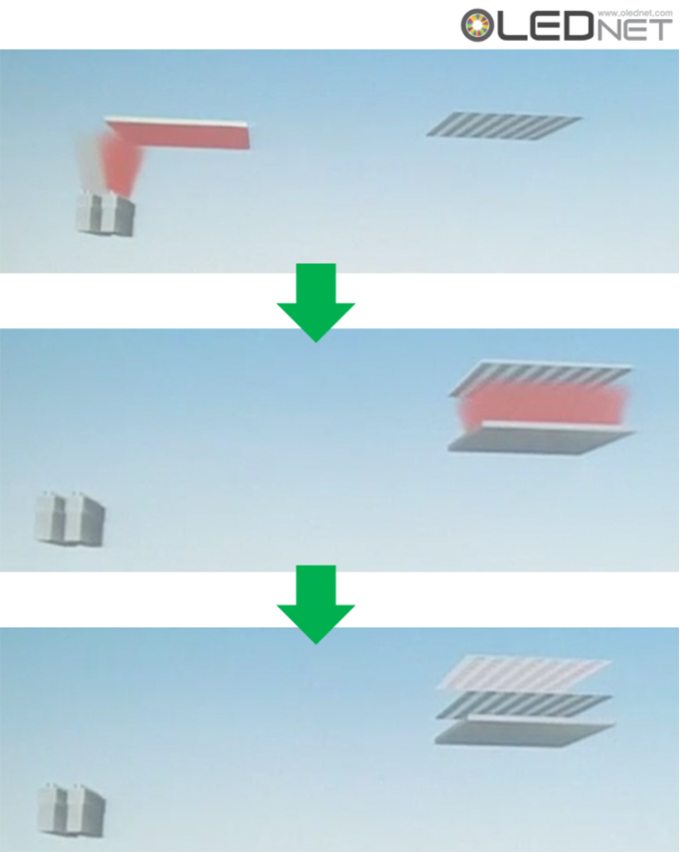

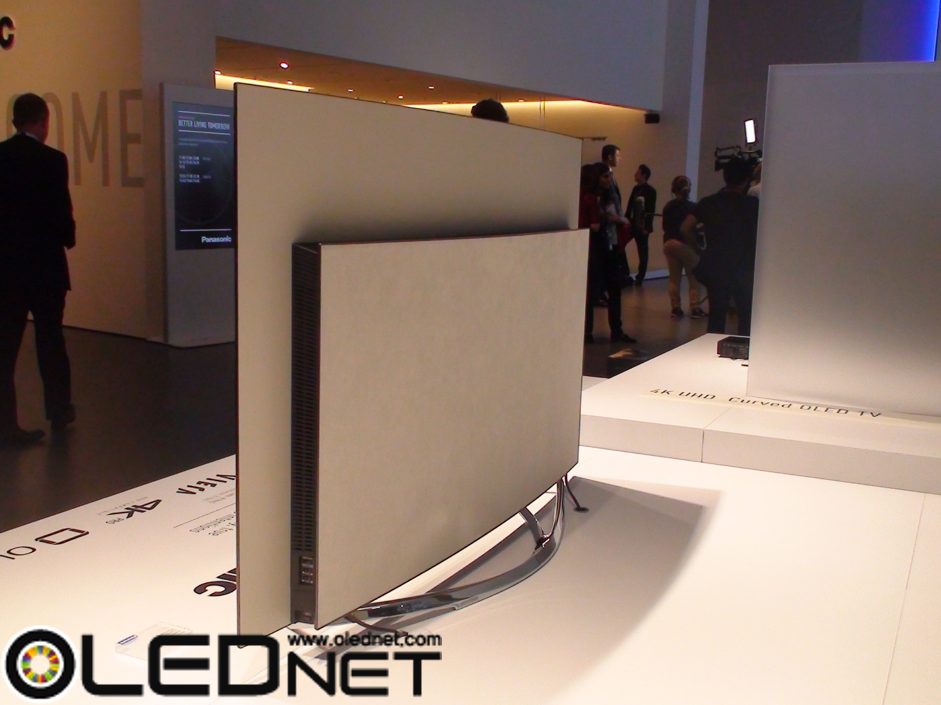

Flexible OLED has thin, light characteristics and a nature to be able to bend, so it is favorable to mirror-less automobiles requiring new designs from free installing aspects. Also, mirror-less is being evaluated to be suitable to the display for automobiles because it can implement high visibility with very fast speed, contrast range, and wide viewing angle. On July 1st last year, Continental Corporation, auto parts supplier, revealed the possibility of better eyesight provision even in dark situations or the rain while introducing several merits of mirror-less automobiles to which 2 OLEDs were applied through its homepage. In addition, Alfred Eckert, Director of the Advanced Engineering department in Continental’s Chassis & Safety Division mentioned “The effects of unwanted optical phenomena such as glare and weak light can also be compensated”

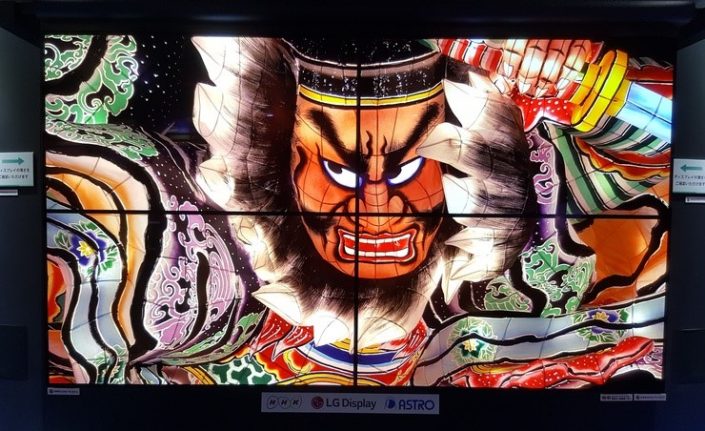

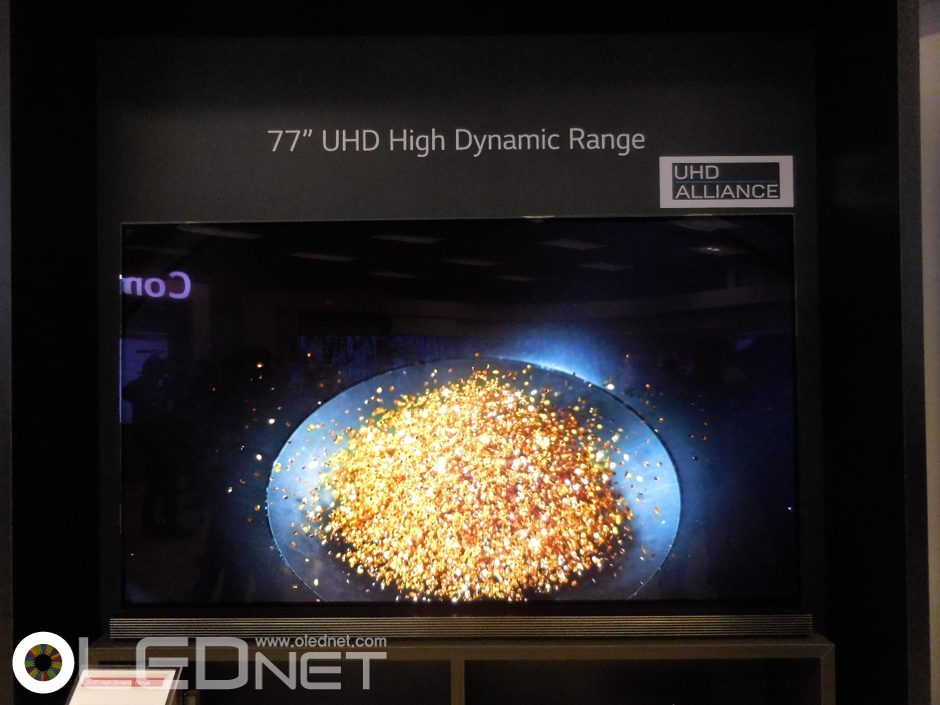

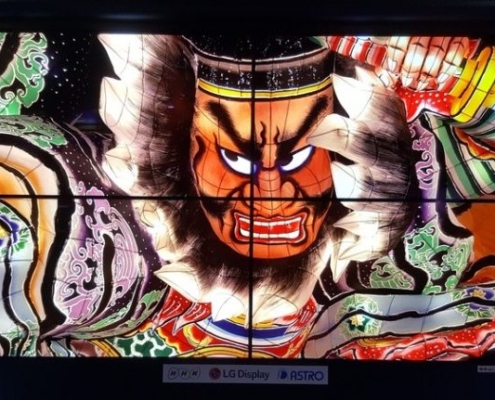

<Mirror-less concept car to which 2 OLEDs were applied> (Source: www.continental-corporation.com)

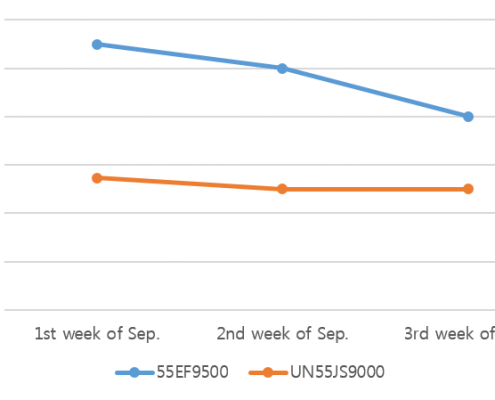

Samsung Electronics is recently propelling automobile electric apparatus business in earnest by taking over Harman, US automobile electric company, and the industry foresees that competency of Samsung Electronics’ OLED and semiconductor would make great synergy effect to electric apparatus business. Furthermore, they lighted up goals such like securing world 30% market share in display for automobiles based on OLED display in 2018, and achieving 2 trillion won in sales.

In this way, OLED display is expected to play core roles in expanding business to electric field industry from electronic/display industry, and it is anticipated that OLED could be a new dynamic to growth of display industry.