LG Electronics Q2 Business Profit 140%↑…Improved Profitability from OLED TV Sales Expansion

Source = LG Elec.

Hyunjoo Kang / jjoo@olednet.com

Source = LG Elec.

Hyunjoo Kang / jjoo@olednet.com

Source = Samsung

Samsung Electronics today announced financial results for the second quarter ended June 30, 2016. Samsung’s revenue for the quarter was KRW 50.94 trillion, an increase of KRW 2.40 trillion YOY, while operating profit for the quarter was KRW 8.14 trillion, an increase of KRW 1.24 trillion YOY.

The second quarter saw significant earnings growth led by strong performance both in the set and component businesses. Overall earnings of the set business improved YOY as well as QOQ due to the continuous sales increase of premium products.

The IT & Mobile Communications (IM) Division saw substantial earnings improvement led by expanded sales of flagship products such as the Galaxy S7 and S7 edge. A streamlined mid-to low-end smartphone lineup also contributed to improved profitability. Operating profit for the IM Division was KRW 4.32 trillion.

The Consumer Electronics (CE) Division achieved significant earnings growth YOY led by strong sales of its premium lineup such as SUHD TVs, Chef Collection Refrigerator, AddWash washer and newly launched air conditioner.

The component business achieved solid performance although overall earnings decreased YOY due to ASP declines in the industry. Earnings for the Display Panel segment improved QOQ led by increased OLED capacity utilization and stabilized LCD panel yields. Demand for semiconductors for mobile and SSD increased and the company achieved solid growth with a competitive edge in differentiated products, including 20-nanometer DRAM, V-NAND and 14-nanometer mobile AP.

The company estimated that the stronger Korean won against major currencies in the second quarter negatively impacted operating profit by approximately KRW 0.3 trillion, reflected mainly in the component business earnings.

Looking ahead to the second half of 2016, the company expects its solid performance to continue compared to the first half, mainly driven by earnings increase in the component business due to sales growth in high value-added products and stable demand and supply conditions. The set business is expected to continue its stable earnings while the IM Division expects marketing expenditure to increase.

In the third quarter, the company expects the component business to maintain its solid performance due to improved demand and supply conditions for memory chips and LCD panels and stable earnings for OLED and System LSI. For the set business, the company forecasts marketing expenditure for the IM business to increase mainly due to a new flagship product launch and fierce competition in the industry. Meanwhile, weak seasonality is likely to impact the CE business.

Capital expenditure (CAPEX) for the second quarter was KRW 4.2 trillion, which includes KRW 2 trillion for the Semiconductor business and KRW 1.6 trillion for the Display Panel business. The accumulated total CAPEX for the first half was KRW 8.8 trillion.

The annual plan for CAPEX has not yet been confirmed but is projected to increase slightly compared to last year. This year’s CAPEX will be concentrated on OLED and V-NAND capacity as the company sees strong market demand for OLED panels for smartphones and V-NAND SSD.

The Semiconductor business posted KRW 12 trillion in consolidated revenue and KRW 2.64 trillion in operating profit for the quarter.

The memory business enjoyed solid growth in demand in the second quarter. Orders for high-density NAND and DRAM products contributed to solid earnings QOQ. This was coupled by a reduction in cost from continuous process migration.

In NAND, shipments of SSD remained strong in the quarter, as enterprise companies increasingly made the transition from HDD to SSD so as to reduce total cost of ownership (TCO). Orders for high-density mobile storage products over 32GB also helped drive sales, mainly due to the expanded adoption by Chinese companies. Samsung actively responded to orders for high-density mobile products over 64GB and enterprise SSD over 4TB and increased supply of the industry’s first 48-layer V-NAND.

In DRAM, demand climbed QOQ as smartphone manufacturers bought more high-density mobile DRAM and demand for high-density products increased following the launch of a new server platform.

A supply imbalance of some applications led to greater demand for Samsung’s 20-nanometer high-density, high value-added mobile and server products.

Looking ahead, for NAND, increased adoption of high-density products and strong seasonality will further drive demand growth in the second half. Growth in high-density, premium SSD products will continue, and the launch of new products by smartphone manufacturers is expected to raise demand for mobile storage. However, supply and demand will be tighter in the second half, due to soft industry supply growth.

For DRAM, the launch of new smartphones and the increasing adoption of 6GB memory chips in high-end smartphones will spur shipments of mobile DRAM in the second half. Shipments of high-density server products will be strong, as more data centers make the transition to a new server platform.

The System LSI business saw gains QOQ, thanks to stronger demand for 14-nanometer mobile AP in premium smartphones and increased sales of high megapixel image sensors. In the second half, increased sales of mid- to low-end mobile AP and LSI products are expected to provide a stable revenue stream.

The Display Panel segment posted KRW 6.42 trillion in consolidated revenue and KRW 0.14 trillion in operating profit for the quarter driven by increased shipments of OLED panels and enhanced yields for new LCD TV panel production technology.

For the OLED business, second quarter earnings improved QOQ due to healthy sales of flagship smartphones and increased demand for flexible panels. High fab utilization rates with the help of an expanded mid to low-end product portfolio also contributed to improved earnings.

For the LCD business, the second quarter saw a continuation of QOQ growth under a gradual recovery in the supply-demand balance. The company was able to achieve growth thanks to improved yields for new TV panel production technology as well as expanded TV sales particularly for large-sized UHD panels.

Looking ahead to the second half, the OLED business, Samsung expects demand for OLED panels to rise despite a likely slowdown in the smartphone market. To remain competitive, the company plans to actively address customer demand and reinforce profitability by expanding the proportion of high value-added products such as flexible and high-resolution displays. Samsung will also seek to secure supply capacity according to market demand while expanding its customer base and new applications.

As for the second-half outlook for the LCD industry, Samsung expects supply and demand to improve thanks to increased demand under strong seasonality as well as continuous UHD TV market growth and size migration towards larger screens. In response, the company will focus on enhancing profitability by improving cost competitiveness and expanding its portfolio to high value-added products including ultra-large size, high-resolution and curved panels.

The IM Division posted KRW 26.56 trillion in consolidated revenue and KRW 4.32 trillion in operating profit for the quarter.

Samsung’s earnings improved QOQ thanks to strong sales of its flagship Galaxy S7 and S7 edge smartphones. Additionally the company achieved growth in the second quarter by maintaining the profitability of mid- to low-end models, such as the Galaxy A and J series, and improving the product mix by raising the sales proportion of the Galaxy S7 edge to over 50 percent.

Demand for smartphones and tablets in the second half is forecast to increase, however, market competition is expected to strengthen as other companies release new mobile devices. Despite this outlook, Samsung will focus on YOY earnings increase by strengthening its high-end line-up and maintaining solid profitability of mid to low-end products.

Looking into the third quarter, the release of a new large-screen flagship smartphone will help to maintain solid sales of high-end smartphones led by the Galaxy S7 and S7 edge. Samsung will also focus on expanding smartphone sales including this year’s new Galaxy A and J series and the debut of the Galaxy C series exclusively for the China market.

Samsung will focus on increasing smartphone sales under strong seasonality with the launch of a new model, while expecting marketing expenses to increase QOQ due to seasonality.

As for the Networks business, earnings improved due to increased LTE investment of major carriers in the second quarter.

The Consumer Electronics Division – encompassing the Visual Display (VD), Digital Appliances (DA), Printing Solutions and Health & Medical Equipment (HME) businesses – posted KRW 11.55 trillion in consolidated revenue and KRW 1.03 trillion in operating profit for the quarter.

In the second quarter, global TV demand remained flat YOY due to sluggish economic conditions in major emerging markets that offset the growth experienced in developed markets. Amid these challenging conditions, Samsung achieved solid YOY earnings by successfully launching new products, including SUHD TVs, and increasing sales of premium products on the back of global sporting events.

For the appliances business in the second quarter, although growth momentum continued in North America, global demand declined YOY due to slower growth in China and the impact from the economic slowdown in emerging markets. Despite these circumstances, earnings improved from the same period of the previous year thanks to increased sales of premium products such as the Chef Collection refrigerator and the AddWash and activ dualwash™ washing machines.

Looking ahead to the second half, TV demand is expected to decline YOY due to weakened demand in Europe and a prolonged economic slowdown in emerging markets. In response, Samsung will focus on improving profitability and increasing sales through collaborations with local channel partners and through region-specific promotions. To reinforce its leadership in the premium TV segment, the company will also seek to grow sales of its premium SUHD TV line-up, particularly products featuring its Quantum Dot technology.

Concerning the outlook for appliances in the second half, market growth is expected to be limited due to the aforementioned concerns in Europe and emerging markets. Despite these conditions, Samsung will actively seek opportunities to counter the challenging market dynamics by launching innovative products that offer superior consumer experiences. The company also plans to achieve further growth by enhancing its B2B business in this sector, particularly for built-in kitchens and system air conditioners.

Source = LGD

Hyunjoo Kang / jjoo@olednet.com

LG Display ( LGD ) reported today unaudited earnings results based on consolidated K-IFRS (International Financial Reporting Standards) for the three-month period ending June 30, 2016.

LGD announced its seventeenth straight quarterly operating profit at KRW 44 billion, which resulted from a thorough and profit-focused management based on differentiated technologies in response to difficult market conditions caused by continuing falls in panel prices and the aggressive expansion of LCD production capacity by Chinese panel makers.

To deal with the difficult market situation, LGD increased profitability by expanding the production share devoted to large-size panels of 60-inches and above as well as premium TV panels embedded with HDR(High Dynamic Range) technology, while continuously leading the Ultra HD TV panel market for 40-inches and above based on its differentiated M+ technology. The company also maximized production efficiency over all its business areas by improving the manufacturing process and producing profit-focused products.

Panels for TVs accounted for 39% of the revenue in the second quarter of 2016, tablets and notebook PCs for 18%, mobile devices for 27%, and desktop monitors for 16%.

With 83% in the liability-to-equity ratio, 145% in the current ratio, and 19.6% in the net debt-to-equity ratio as of March 31, 2016, the financial structure of the company remains stable.

LG Display will continue to make efforts to improve profitability by focusing on premium products including large-size Ultra HD TV displays based on its M+ technology and IPS In-Touch displays in the second half of the year, while driving expansion of the OLED market and its customer base.

As for large-size OLED TV panel, the company will increase cost competitiveness through further stabilizing production and improving the manufacturing process of Ultra HD products, while continuing promotion with customers to strengthen the premium positioning of OLED TV. It will also establish a competitive edge through timely investments in cutting-edge technologies for the future including flexible OLED displays.

Mr. Don Kim, CFO of LG Display, said “Display area shipments in the third quarter are expected to increase by a mid-single digit percentage compared to the second quarter due to seasonal factors and the growing trends towards large-size panels. Overall profitability in the second half of the year is expected to further improve due to stabilized panel prices.” He also added, “LG Display will put its best efforts to create differentiated value in terms of profitability, while preparing for future growth even under difficult market conditions.”

LGD will invest KRW 1.99trillion in 6G flexible OLED line. (Source = LGD)

Chinese and Taiwanese Gen8 line is higher than Korea’s Gen8 LCD capa. (Source = BOE)

Hyunjoo Kang / jjoo@olednet.com

In order to respond to the outpouring Chinese large area LCD, it is analyzed that carrying out investment to turn large area LCD line into OLED is the most reliable method.

According to 2016 OLED Manufacturing Equipment Annual Report, recently published by UBI Research, Chinese and Taiwanese panel companies’ Gen8 or higher LCD mass production line is 690K in total as of Q1 2016. This is higher than Korea’s Gen8 LCD capa.

Even now, China is showing active movements in additional establishment of large area LCD mass production line. UBI Research forecasts that in 3 years, China and Taiwan’s new large area LCD mass production line will reach up to 80% of the Korea’s current mass production capa. The report emphasizes that to fight against this great supply volume from Great China region, Korean panel companies should change the large area LCD line to OLED.

In case of Gen8 line, unlike small-to-medium size line, the LCD line can be cost effectively transformed to OLED line. As such, it is considered to be the main object for the complementary investment.

Particularly, if oxide TFT, which has few photomask processes, and WRGB+CF technologies are applied, existing large area a-Si LCD line’s manufacturing equipment can continue to be used.

UBI Research explained that an advantage of complementary investment is the fact a-Si LCD line’s backplane equipment and color filter equipment can continue to be used. He further added that in order to maximize a-Si line’s capa., development of TFT process with few photomask processes is a necessity.

Picture Source = SDC

Hyunjoo Kang / jjoo@olednet.com

In order to respond to rapidly increasing OLED smartphone demand, Samsung Display( SDC ) is analyzed to require additional installation of Gen5.5 rigid OLED line and V1 line move.

At present, China’s smartphone OLED demand is explosive. According to UBI Research’s investigation, China needs up to 200 million units of mobile OLED until next year. Therefore, for Samsung Display to produce more OLED panels in A2 factory, V1 line that produces transparent OLED needs to be moved to L8 which is a Gen8 LCD factory.

OLED use V1 line has been using Gen8 manufacturing equipment produced TFT substrate cut into 6. As such, moving the V1 line to Gen8 factory is analyzed to be advisable in terms of panel production and distribution management.

The president of UBI Research, Choong Hoon Yi explained that China’s future mobile OLED demand volume is difficult for China’s key panel companies such as BOE, and even for mobile OLED leader Samsung Display it is not easy to supply sufficient amount with existing mass production line. He estimated that Samsung Display, to meet the demand, will require additional installation of at least 20-30K OLED mass production line to Gen5.5 A2 line.

2016-2020, global Gen8 complementary investment ( LCD → OLED ) is expected to be total USD 6,674 million.

Hyunjoo Kang / jjoo@olednet.com

For the next 5 years, 2016-2020, global Gen8 (8G) complementary investment ( LCD → OLED ) is expected to be total USD 6,674 million.

According to 2016 OLED Manufacturing Equipment Annual Report, recently published by UBI Research, Korea’s 8G complementary investment in 2016-2020 is estimated to be USD 5,400 million, 81% of the global USD 6,674 million. Particularly, complementary investment for large area LCD line to OLED is expected to be actively carried out centering around LG Display.

China is estimated to actively operate new large are LCD lines from 2016. To respond to this move, Korean panel companies are expected to transform 8G a-Si LCD lines located in Korea to OLED line from 2016.

To respond with LCD, China’s supply offensive and price competitiveness are too strong. As such, the situation calls for concentrated efforts in OLED.

Gen8 LCD line became the object of complementary investment as it can be easily converted to OLED compared to small-to-medium size LCD line. 8G LCD line’s a-Si TFT can be turned into oxide TFT used in Gen8 OLED line cost effectively.

Source = Cynora

Hyunjoo Kang / jjoo@olednet.com

CYNORA, a leader in blue TADF (thermally activated delayed fluorescence) materials, has appointed Dr. Andreas Haldi as its Chief Marketing Officer.

With his strong technical and business experience, Andreas Haldi will reinforce CYNORA in the forthcoming commercialization of its high performance blue OLED materials.

CYNORA is preparing the commercialization of its emitting materials for OLEDs. The company is hiring Andreas Haldi to further enhance its already good relationships with the major display makers and to now prepare with them the implementation of its materials in their products.

Andreas Haldi has close to 15 years of experience in the OLED materials field and profound knowledge of the Asian display market. Prior to joining CYNORA, Haldi held manager positions in R&D and sales at Novaled GmbH. For the last five years he was headquartered in Seoul, Korea, as Novaled’s representative in front of the major AMOLED display makers in Asia.

“I am very happy to get Andreas on board” says Gildas Sorin, CYNORA’s CEO. “We are preparing ourselves intensively for the commercialization of our blue emitters. Thanks to his proven skills on OLED and his experience in Asia, Andreas will help us to build up our success as a leading supplier for TADF materials.”

“I am looking forward to joining CYNORA” says Andreas Haldi, “CYNORA has shown its expertise and its impressive capability to progress rapidly during the last 8 months. CYNORA has a great potential to become key player in the OLED material industry.”

The appointment of the new CMO is a significant signal of CYNORA’s further development and its forthcoming market entry. Blue TADF-based emitters will enable a significant reduction of power consumption in OLED devices and will allow higher display resolution. CYNORA owns a broad IP portfolio with over 100 patent families and is aiming for over 600 patents.

LGD`s 65“ OLED TV Panel

Source = BOE ( China )

Hyunjoo Kang / jjoo@olednet.com

China is expected to possess 80% worth of new large size LCD line of current Korean large size LCD mass production line after 3 years.

According to 2016 OLED Manufacturing Equipment Annual Report, recently published by UBI Research, the total monthly production capa. of large area LCD mass production line that has been confirmed or being considered for investment in China and Taiwan until the end of 2018 is 525K. This is based on the results of UBI Research’s investigation on Q3 2016 – Q4 2018 investment plans of Chinese and Taiwanese companies including BOE, HCK, CEC Panda, CSOT, AUO, and Innolux.

If the plan is carried out without any issues, the order is expected to be completed by Q4 2018, and after equipment installation, the lines are to be ready to operate in 2019.

The monthly capa. of 525K is 80% of the current total LCD mass production line of Korea. Once 525K new lines begin to operate, oversupply of large size LCD panel is expected to actively occur.

UBI Research estimated that if China and Taiwan’s large area LCD investment is carried out according to plan, it will be difficult for Korean and Japanese large size LCD panel to compete against Chinese panel.

Source = AUO

Hyunjoo Kang / jjoo@olednet.com

LCD shipment of AU Optronics (AUO) in Q2 2016 increased but revenue decreased.

AUO recently announced that they recorded revenue of NTD 80.09 billion (approx. USD 2,478 million) in Q2 2016. This is an increase of 12.6% from the previous quarter but down 13.2% from Q2 2015.

AUO’s panel shipment in Q2 was 70.96 million units with 28.46 million units of 10-inch and above panels, and 42.5 million units of 10-inch and below panels. The large size panels increased by 16.5% QoQ, and by 14.3% YoY. The small to medium size panels increased by 12.6% QoQ, and by 11.5% YoY.

Basically, this company sold more and earned less demonstrating that LCD price fall aftermath continued into Q2.

The H1 2016 revenue of Novatek, Taiwan’s LCD driver IC company, fell by 10.9% compared to H1 2015. LCD surface mount company TSMT’s Q2 revenue fell by 10.1 compared to Q2 2015.

Intel, LG Display, Dolby Laboratories, Audi and more slated to preset at the OLEDs World Summit 2016

Join top OLED display, lighting and material developers at the 18th annual OLEDs World Summit, taking place September 20-22 at the Paradise Point Resort & Spa in San Diego, CA. For nearly two-decades, the OLEDs World Summit has served as a homecoming for the display and lighting industries and provided a platform for them to highlight successes, address challenges and network. This year you can expect a complete overview of the industry.

The OLEDs World Summit 2016 will kick off by examining flexible display applications including wearable devices, smart phone applications and more. Over the course of the event, attendees will also explore chemicals and tools for OLEDs, new applications, challenges for OLED materials in displays and much more. As an attendee you can expect to hear discussions such as:

In addition to the presentations and dynamic discussions, there are four keynote presentations by some of the biggest names in the industry. You’ll hear from:

Register today!

Your colleagues from Eastman Kodak, Acuity Brands Lighting, Universal Display, LG Display and more have already reserved their delegate tickets. Book your ticket today for the low price of $1199. Hurry, the price goes up after July 13th!

Questions?

Contact the Graphene World Summit Team:

Agenda Questions-DeAna Morgan at dmorgan@smithers.com

Media Questions-Katie Oster at koster@smithers.com

Sponsorship Questions-Emily Murray at emurray@smithers.com

QLED is Becoming an issue (Picture Source = Samsung Elec.)

UBI Research Chief Analyst Choong Hoon Yi

As the next generation TV technology, QLED is becoming an issue in media. This is because Samsung Electronics selected QLED TV as the next product after the currently selling SUHD TV. However, if QLED TV display is the product that uses electroluminescence quantum dot, this shows they do not know display at all.

Quantum dot technology display can be divided into 2 types depending on the light-emitting technology. Photoluminescence quantum dot technology uses mechanism where the materials stimulated by external light emits light again, and this QD technology is currently applied to LCD TV. The TV has quantum dot sheet attached to the backlight’s blue light to be used as the backlight unit, and Samsung Electronics’ SUHD TV is such a product.

As photoluminescence quantum dot has wide color gamut, this can actualize over 110% of NTSC standards and there is no doubt that this is the best LCD TV product. Furthermore, another photoluminescence quantum dot technology, where colors are actualized by dispersing quantum dot materials on color filter, is in development.

In comparison, electroluminescence quantum dot technology is self-emitting when electricity is applied, and similar to OLED. Only the light emitting materials are inorganic and the structure is comparable to OLED. For OLED, hole is introduced from electrode through HIL layer, and this hole reaches emitting materials through HTL layer to produce light.

When the electron reaches emitting materials through EIL and ETL layers, the emitting materials with rapidly increased energy level due to electron and hole, produces light to release the energy. HIL, HTL, EIL, and ETL layers are needed in OLED to control the energy levels needed for electron and hole to reach emitting materials.

Therefore, for electroluminescence quantum dot to emitting light, HIL, HTL, EIL, and ETL layers are required same as OLED. Scientists developing electroluminescence quantum dot technology are using OLED HIL, HTL, EIL, and ETL materials. As the exclusive materials have not been developed, the technology is still in early stages.

This still belongs in science category rather than technology. Furthermore, electroluminescence quantum dot is dispersed to solution to print, and as such ink-jet or similar equipment development is necessary. HIL, HTL, EIL, and ETL also have to be dispersed using solution.

What is curious is whether Samsung Electronics’ QLED TV is existing QD technology that uses photoluminescence quantum dot or technology that uses electroluminescence quantum dot. Generally, QLED signifies electroluminescence quantum dot.

Therefore, if Samsung Electronics can really sell electroluminescence quantum dot using QLED within a few years, this will place Samsung Electronics as the world’s most innovative company establishing new scientific records.

However, OLED emitting materials developing companies are dismissing this claim as ridiculous. Solution process produced OLED emitting materials, HIL, HTL, EIL, and ETL materials have not yet been suitably developed, and require 5 more years before commercialization. As such, companies believe that actualizing QLED in a few years is impossible.

The fact is QLED exclusive HIL, HTL, EIL, and ETL materials are not being developed yet. Printing equipment also have not yet been commercialized. Electroluminescence quantum dot developing academia also points out that only the potential has been glimpsed so far.

Several stages have to be passed through for QLED to be realized. For solution process using QLED to be commercialized, it could only happen after solution process OLED appears first. Looking at the history of OLED commercialization, this is minimum 10 years.

For Samsung Electronics that cannot produce OLED TV to have mentioned that they will produce QLED TV within 3 years makes the writer wonder whether to exclaim, “only Samsung” in awe or ask “what is Samsung doing?”

Source = LG

(Unit: KRW bn)

These figures are the tentative consolidated earnings based on K-IFRS. This tentative earnings is provided as a service to investors prior to LG Electronics’ final earnings results including net profit and details regarding each division which will be announced officially later this month.

Hyunjoo Kang / jjoo@olednet.com

Samsung Elec. announced its earnings guidance for the second quarter of 2016.

Samsung Elec. estimates that consolidated sales came to approximately KRW 50 trillion, and consolidated operating profit of approximately KRW 8.1 trillion.

The above figures are estimates of consolidated earnings based on K-IFRS. Korean disclosure regulations do not allow earnings estimates to be provided as a range. Therefore, the above figures are based on the median of the earnings estimate range, as given below.

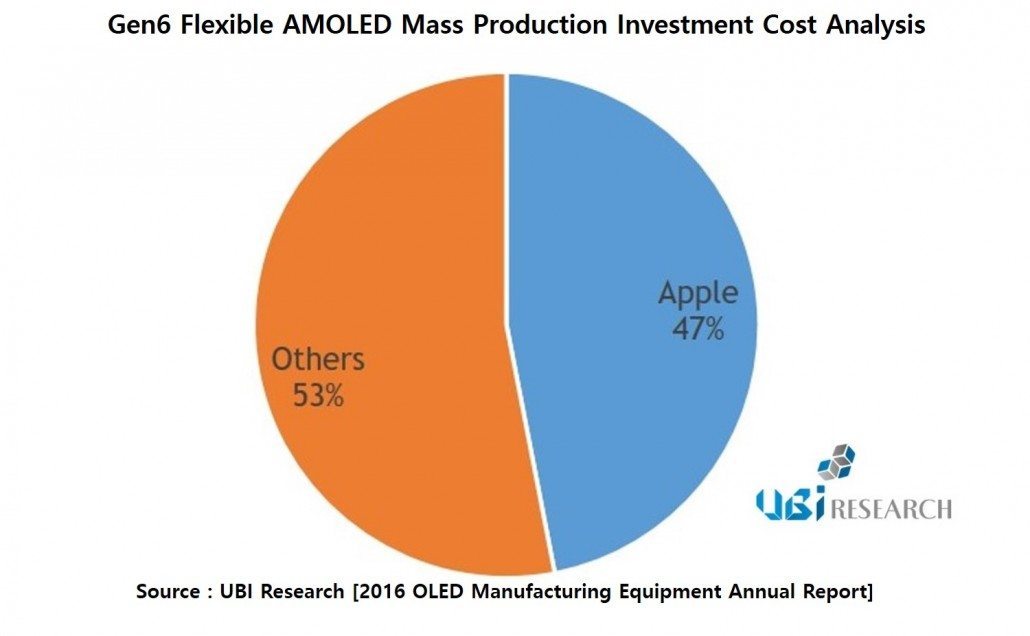

Source = UBI Research [2016 OLED Manufacturing Equipment Annual Report]

AMOLED manufacturing equipment market for Apple’s use for 5 years, 2016-2020, is expected to reach USD 13,000 million.

According to 2016 OLED Manufacturing Equipment Annual Report, published on 7 July by UBI Research, the global Gen6 flexible AMOLED manufacturing equipment market is expected to record USD 28,411 million in 2016-2020. 47% of this is for Apple’s use with USD 13,000 million. The figure is if Apple applies flexible panel to some new models of iPhone to be released in 2017, and all new models to be released in 2018.

Apple occupies approximately 15% of the total smartphone sales with over 200 million units per year. As such, it is expected to have great impact on future exible panel market expansion.

In 2021, global flexible AMOLED panel shipment is estimated to exceed 1,000 million units. UBI Research forecasts Apple iPhone’s flexible panel will occupy 20% of the total flexible AMOLED shipment in 2017, and exceed 50% in 2021. UBI Research explains that in order to meet Apple’s flexible AMOLED panel demand, the required panel production capa. is analyzed to be 30K per month in 2017, and total 300K per month in 2021.

Furthermore, panel companies’ mass production line is expanding accordingly, and Samsung Display in particular is expected to invest 30K per year directed to Apple.

UBI Research’s latest report forecasts that the total OLED manufacturing equipment market to record approximately USD 43,927 million in 2016-2020.

출처 = Applied Materials

Hyunjoo Kang / jjoo@olednet.com

Applied Materials is expected to show Q2 display manufacturing equipment sales increased by almost 6 times bolstered by OLED market growth.

Digitimes recently quoted Applied Materials’ greater China account general manager Kuo Yi-tze and reported that the company’s Q2 2016 order value for the display manufacturing equipment is estimated at USD 700 million. This is a 5.8 times increase compared to USD 120 million in Q2 2015.

Particularly, the demand by Korean panel companies, including Samsung Display and LG Display, is rapidly increasing. Furthermore, Chinese panel companies are also actively taking action to catch up to Korean panel companies’ technology and production ability.

Applied Materials estimates that the global shipment of mobile device OLED panel for smartphone, smartwatch, etc. will increase from 2016’s 353 million to 2020’s 799 million units. Furthermore, automotive OLED panel shipment is expected to increase from 2016’s 134 million to 2020’s 176 million units.

Applied Materials has seen orders for OLED equipment increasing, especially from South Korea-based panel makers, and its second-quarter 2016 order value for the display equipment segment is estimated at US$700 million, 5.8 times the US$120 million recorded for second-quarter 2015, according to Applied Materials’ greater China account general manager Kuo Yi-tze for AKT Display Business Unit.

South Korea-based panel makers take significantly lead in OLED technology and production and China-based fellow makers are making efforts to catch up, Kuo said.

Demand for OLED panels mainly comes from growing application to smartphones and smart watches, with global shipments of OLED panels used in mobile devices to increase from 353 million units in 2016 to 799 million units in 2020, Kuo indicated.

In addition, global shipments of OLED panels used in automotive displays will increase from 134 million units in 2016 to 176 million units in 2020, with a CAGR of 9% in unit shipments and 12% in area shipments during 2016-2020 Kuo noted.

UBI RESEARCH / CEO:Choong Hoon Yi / Business License Registration Number 220-87-44660

ADDRESS: A-1901, Samho Moolsan Bldg, 83, Nonhyeon-ro, Seocho-gu, Seoul, Republic of Korea (Zip) 06775 TEL:+82-2-577-4390 / E-MAIL:marketing@ubiresearch.com